Questions and answers on the subject of eyewear

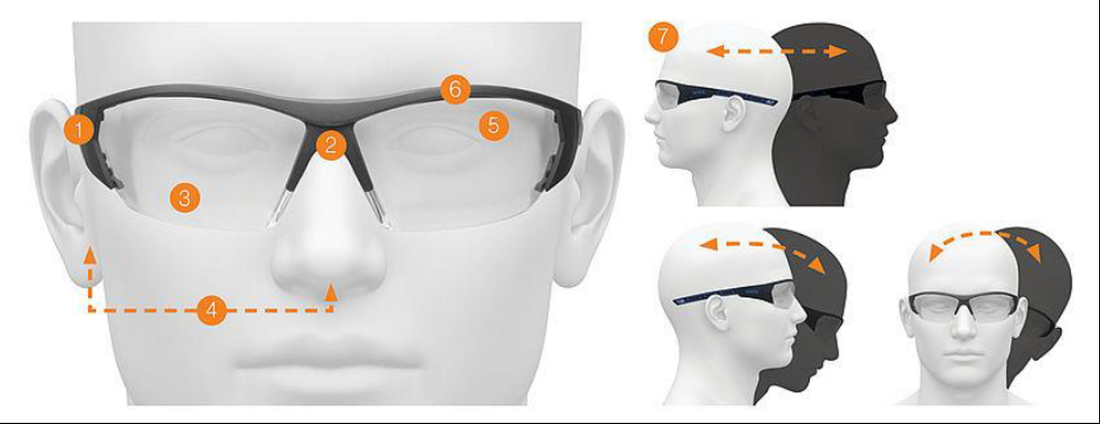

We recommend the following 7 steps to check whether your safety glasses are sitting properly:

- You shouldn’t be able to feel any uncomfortable pressure points at the side of your head and behind your ears

- The nose pad should be comfortable and sit on the nose without pinching

- You should be able to see clearly and have an unrestricted view in all directions

- The total weight of the safety glasses should be evenly distributed between your ears and nose so that the frame sits comfortably on your face without distracting you from the tasks you have to carry out

- The frame or lens should sit close to your face without touching your eyelashes.

- The gap between the lens and your face should be narrower than a pen (<=6-8mm) The frame or lens should cover the eyebrows and all other soft areas

- The glasses should sit firmly on your head when you move your head in all direction

We recommend storing your safety glasses in their original packaging in a dark, dry place, where the product will not be subjected to mechanical loads, the temperature is below 40°C and air humidity is below 70%. If stored correctly, the safety glasses will have a shelf life of six years from the date of manufacture. The date of manufacture is shown in clock format (the arrow accompanied by the last two digits of the year points towards the month of manufacture) or factory icon (month/year) on the safety glasses and their packaging.

The service life of a pair of glasses depends on the workplace environment and the way in which they are handled at the workplace and cannot therefore be determined on a general basis. The recommended service life is a maximum of two years from first use, depending on the intensity of use, frequency of use and wear caused by external factors; the date of first use should be recorded.

uvex recommends wearing full wide vision safety goggles where either tightly sealed safety glasses need to be worn to protect the eyes against hazards, or where there is a risk of medium energy flying particles causing safety spectacles to fly off your head. This means, for example, when using low speed grinders and machining metals, working in dusty conditions (goggles marked 'D' for dust protection), or when handling dangerous substances such as decanting chemicals goggles marked ‘C’ for splash protection. However, it is always advisable in individual cases to have a safety specialist or safety authority carry out a safety assessment.

There are no defined tests for resistance against chemicals set out in the AS/NZS 1337.1 standard, as is the case with chemical protective gloves, for example. In principle, all uvex wide vision safety goggles marked 'C' for splash protection offer a first barrier of resistance against chemicals. Depending on the chemical, however, the mechanical strength of the wide vision safety goggles may have been affected after contact. The lens material may also become cloudy and therefore no longer be able to guarantee full visibility. uvex therefore recommends that you clean the wide vision safety goggles immediately after contact with light chemicals and dispose of the glasses after contact with dangerous chemicals and use new wide vision safety goggles. Incidentally, this is also the case with chemical protective gloves.

In general, all our glasses are able to withstand temperatures of up to 80°C as far as the material is concerned. However, the following additional points need to be taken into account:

- Mechanical strength (if a T marking in the EN marking is present) is only guaranteed up to a temperature of + 55°C. Resistance beyond this has not been tested.

- Infrared radiation may also occur at high working temperatures, depending on the area of work. In this case, welding protection would be necessary.

- It is possible that at high temperatures, the entire face must/should be protected, i.e. a visor is used.

- Our uvex wide vision safety goggles are available with polycarbonate (PC) as well as cellulose acetate (CA) lenses. It should be noted that the CA material begins to warp at temperatures of +80°C.PC material, on the other hand, retains its shape. We will be happy to advise you if you are unsure whether the glasses you are using will withstand the temperature of your workplace or whether you are using the right glasses. Please do not hesitate to contact our customer service team.

We recommend the following method for cleaning and disinfecting uvex safety glasses:

- Read the information in the instructions provided with the safety glasses

- First clean the glasses under running water. Standard cleaning agents can be used

- If necessary, uvex safety glasses can also be cleaned by disinfectant wipes or sprays. Do not clean the glasses by soaking them in disinfectant. Read the instructions for your chosen disinfectant and clean the glasses in accordance with the instructions with regards to usability, disinfection process and exposure time. If indicated in the instructions for the disinfectant, rinse thoroughly using fresh water afterwards

- Allow to air dry

- Check the respective glasses for any damage after each cleaning cycle and before using them again. Stop using the glasses if you notice any signs of damage

We recommend the following approach for cleaning and disinfecting uvex safety glasses after coming into contact with viruses:

- Read the information on the instructions provided with your safety glasses.

- During cleaning, we recommended wearing disposable gloves made from nitrile or latex.

- First clean the glasses under running water.

- uvex safety glasses can also be cleaned with disinfectant wipes or sprays. Do not clean the glasses by soaking them in disinfectant. Read the instructions for your chosen disinfectant and clean the glasses in accordance with the instructions with regards to usability, disinfection process and exposure time. If indicated in the instructions for the disinfectant, rinse thoroughly using fresh water afterwards.

- Allow to air dry in a non-contaminated area.

Please note that uvex has not tested which disinfectant has an anti-viral effect, nor which is best-suited to the respective uvex product. Some of the recommendations made by the Robert Koch Institute apply to anti-viral disinfectants. Prolonged contact time, frequent use of disinfectant products or high drying temperatures can damage the coatings and other components of the glasses. As a user, you must check the glasses for damage after each cleaning cycle and before using them again. Stop using the glasses if you notice any signs of damage.

We recommend that you do not use silicone-based cleaning agents to clean our safety glasses. These can attack the coating, which may result in the anti-fog property being lost. There is also a risk of a deposits forming on the coatings. However, it is possible to also clean them using all standard cleaning agents or soap and water.